Application areas

Contact Information

412007, No. 86, Tomorrow Road, Liyu Industrial Park, Tianyuan District, Zhuzhou City, Hunan Province

Contact Phone

WhatsApp:+86 13973326303

Contact: Chen Lianlian 13973326303 Huo Shuqiang13607335099

Laser cladding

Laser cladding (Laser Cladding), also known as laser cladding or laser cladding, is a new surface modification technology. It forms a metallurgical bonding cladding layer on the surface of the base layer by adding cladding material on the surface of the base material and using a high-energy density laser beam to fuse it with a thin layer on the surface of the base material.

The characteristics of laser cladding: the cladding layer has low dilution but strong bonding force, and is metallurgically combined with the substrate, which can significantly improve the wear resistance, corrosion resistance, heat resistance, oxidation resistance or electrical characteristics of the surface of the substrate material, so as to achieve the purpose of surface modification or repair, and save a lot of material costs while meeting the specific performance requirements of the material surface. Compared with surfacing, spraying, electroplating and vapor deposition, laser cladding has the characteristics of small dilution, compact structure, good combination of coating and substrate, more suitable for cladding materials, and large changes in particle size and content. Therefore, the application prospect of laser cladding technology is very broad.

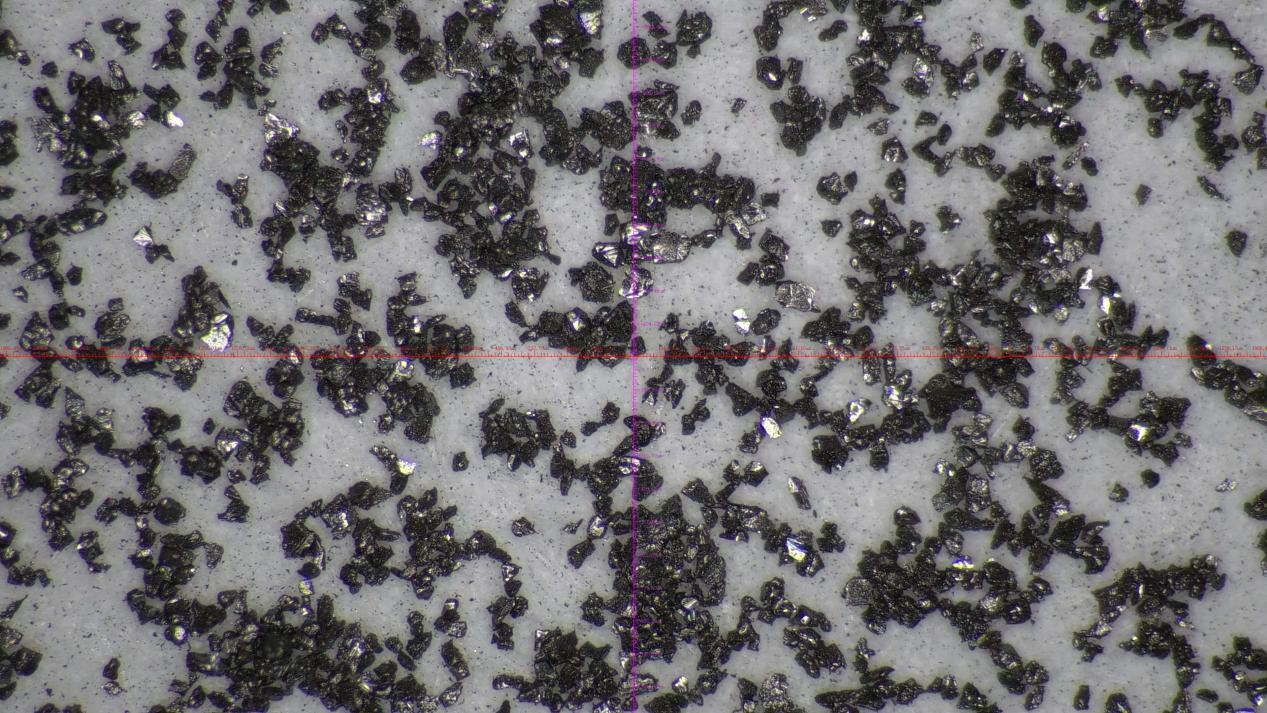

The powder produced by our company can be used as the raw material of laser cladding powder or can be used directly as laser cladding powder, such as coarse-grained titanium carbide, chromium carbide and niobium carbide.